current location : Home » categoires :

Understanding the Role of Surface Finishing in Prototype Manufacturing

Understanding the Role of Surface Finishing in Prototype Manufacturing

In prototype manufacturing, surface finishing plays a crucial role in determining the final product’s aesthetics, functionality, and durability. While the primary goal of prototyping is to validate design concepts and test functionality, surface treatment ensures that the prototype closely resembles the end product in terms of appearance and performance.

Enhancing Aesthetics and Functionality

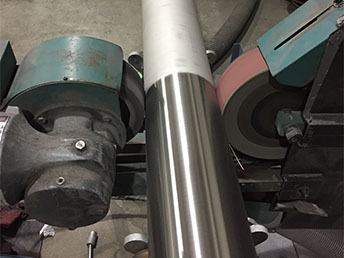

Surface finishing techniques, such as painting, anodizing, sandblasting, and electroplating, enhance the visual appeal of a prototype by improving texture, gloss, and color consistency. Additionally, certain finishes can reduce friction, enhance grip, or provide electrical insulation, making them essential for functional testing in real-world applications.

Improving Durability and Performance

Many prototypes undergo surface treatments to improve wear resistance, corrosion protection, and mechanical strength. For instance, anodizing aluminum parts creates a hard and corrosion-resistant layer, while powder coating provides a durable finish for plastic and metal components. These treatments help extend the lifespan of prototypes, especially in harsh environments.

Aligning with Production-Grade Standards

Prototypes that mimic production-grade finishes provide better insights into how the final product will look and perform. This is particularly important for industries like automotive, aerospace, and medical devices, where regulatory compliance and material properties are critical. By applying appropriate surface treatments, manufacturers can refine designs and avoid costly modifications later in production.

Choosing the Right Surface Finish

The choice of surface finishing depends on the prototype’s purpose, material, and intended application. Whether it’s a simple aesthetic enhancement or a protective coating for functional validation, selecting the right finish ensures a more accurate and reliable prototype.

At LEADMAKE, we offer a wide range of surface finishing options to meet your specific prototyping needs. Contact us today to explore how we can help bring your designs to life with precision and quality!

prev Top Trends in Custom Manufacturing What You Need to Know for 2025

next Successful Delivery Shaving Razors Transported!