current location : Home » categoires : 3D Printing Service

How does SLA Plastic 3D printing work?

How does SLA Plastic 3D printing work?

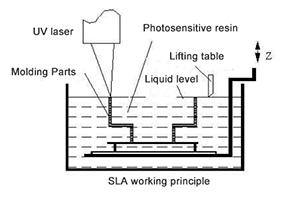

The principle of SLA rapid prototyping:

The computer-controlled laser beam scans the surface of the raw material point by point, and the resin thin layer (0.1mm) in the scanned area undergoes photopolymerization reaction to solidify, forming a thin layer of the part. Move the workbench down by a thickness of one layer, so that a new layer of liquid resin can be applied to the cured resin surface for the next layer of scanning processing. Repeat this process until the entire prototype is manufactured.

- The SLA process generally requires cleaning, de supporting, polishing, and re curing to obtain products that meet the requirements.

- The SLA process requires support to be added to the suspended wall area, and the product and support are made of the same material.

- For color models, later color treatment is also required.

Advantages of SLA 3D printing:

The SLA process is very beneficial for those who need to produce high-precision, high surface quality, and multi detail plastic parts for prototype design and simulation, appearance verification, assembly verification, and functional testing as well as for those in low volume production.

(1) High precision, smooth surface, capable of producing large-sized products;

(2) Good rigidity, excellent sharp angles, and small shrinkage;

(3) Excellent surface details, extremely textured, and fast production speed;

(4) There are various types of resins (white, semi transparent, fully transparent, high toughness, etc.) to meet various performance requirements.

What materials can you choose for SLA 3D printing?

|

Characteristic |

Material |

Material name |

Color |

Tolerance |

Max size(mm) |

|

Favorable price |

White regular resin |

UTR 3100P |

White |

±0.1mm or 0.1% |

1400*700*500 |

|

Suitable for thin parts |

White good resin |

Somos® GP Plus |

White |

±0.1mm or 0.1% |

600*600*400 |

|

High dimensional stability |

White toughness reisn |

Somos® Ledo 6060 |

White |

±0.1mm or 0.1% |

600*600*400 |

|

Both toughness&strength |

Chartreuse toughness resin |

Godart™ 8228 |

Chartreuse |

±0.1mm or 0.1% |

800*800*550 |

|

High transparency |

Transparent resin |

Godart™ 8001 |

Transparent |

±0.1mm or 0.1% |

600*600*400 |

|

High toughness |

Black toughness resin |

Somos® Taurus |

Dark gray |

±0.2mm or 0.2% |

600*600*400 |

Parts Structure Requirements for SLA resin printing:

(1) Min wall thickness: 0.6mm (large area thin thickness should be greater than 2mm);

(2) Min independent column diameter: 1mm;

(3) Min stroke width for convex (concave) characters: 0.35;

(4) Min hole diameter: 1mm;

(5) Minigap: 0.4mm;

Surface treatment for SLA resin printing:

Products without polishing treatment may have layer patterns on the surface, which can be polished off. It is suitable for various surface treatment processes such as polishing, sandblasting, spraying, dyeing, screen printing, and electroplating.

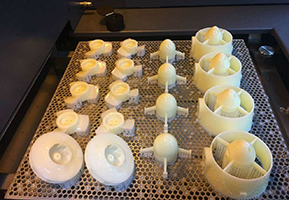

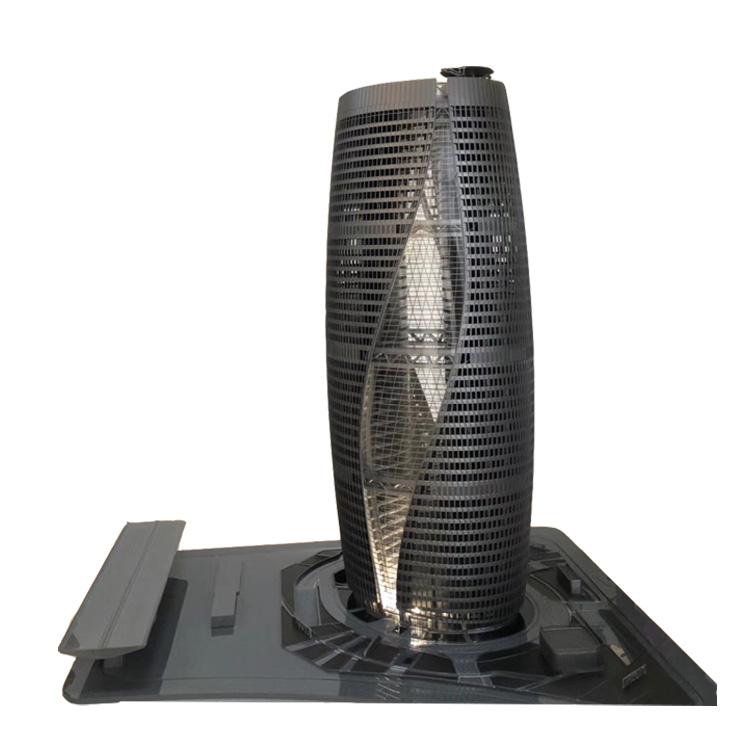

Case studies of SLA Plastic 3D printing:

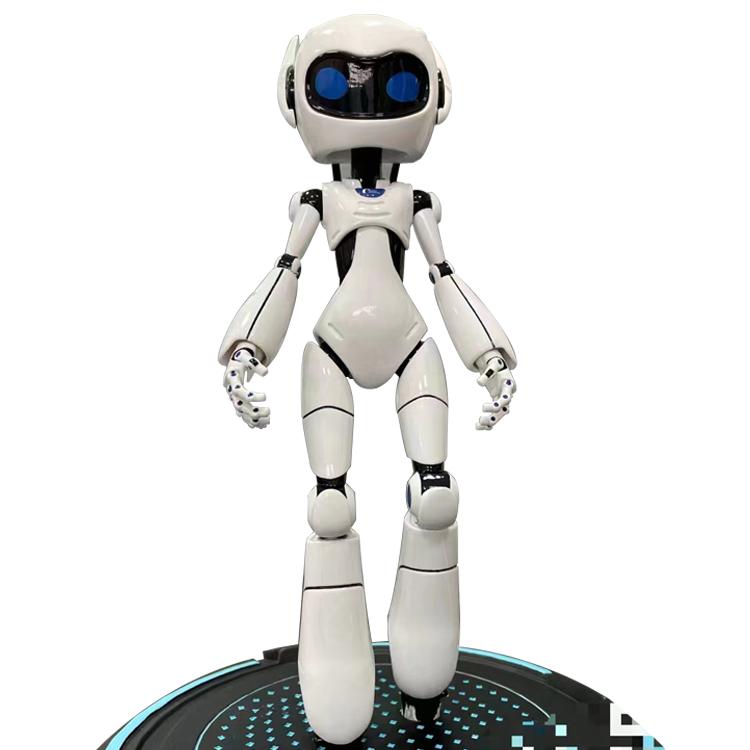

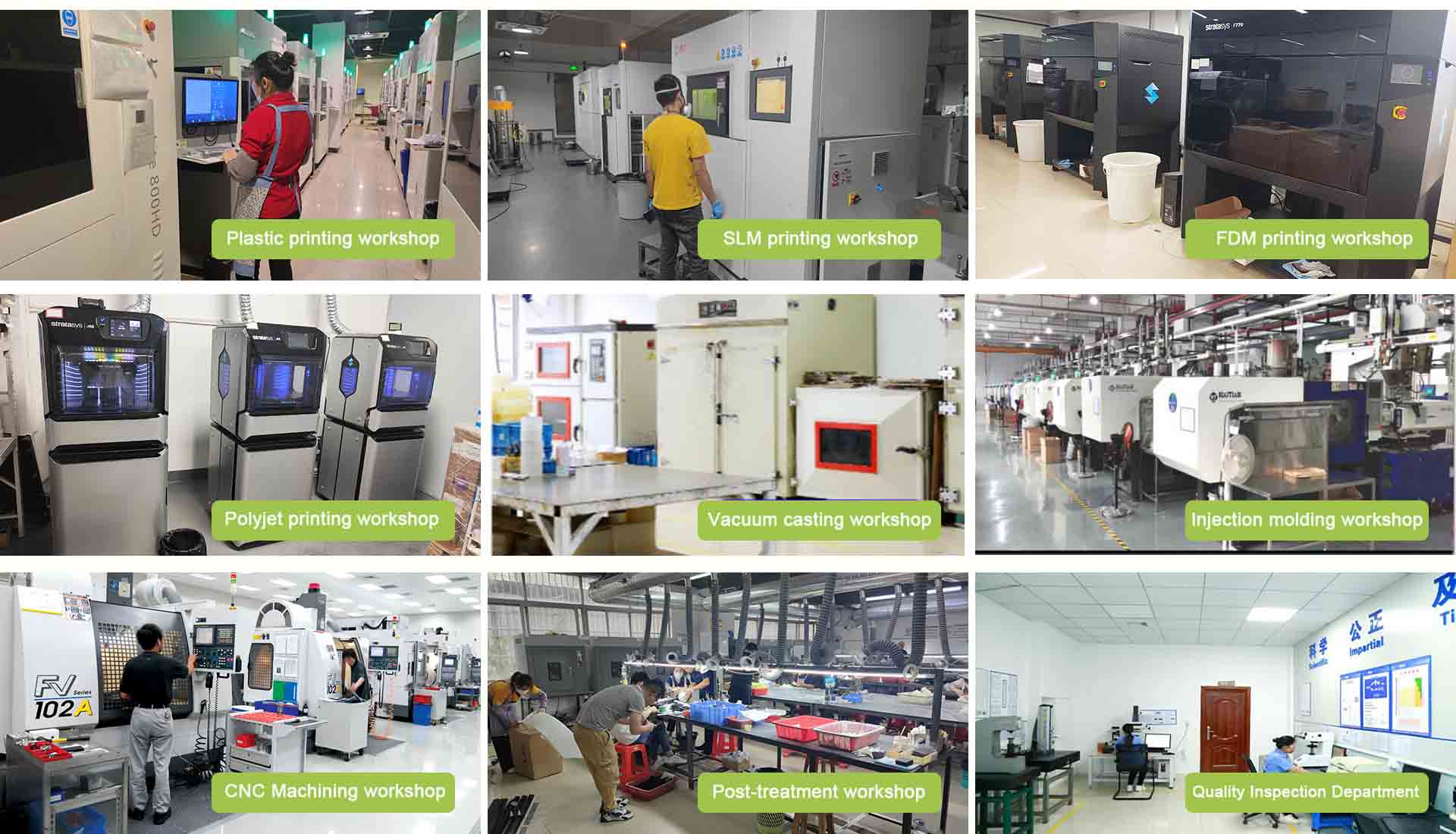

YYI Tech Factory and equipment display

300+sets rapid prototyping equipment, complete materials, complete processes, and comprehensive equipment to meet your various customization needs

About YYI Tech

A professional one-stop rapid prototyping manufacturer

Dongguan Yyi Technology is a professional OEM plastic parts & Metal Fabrication factory located in Dongguan, China and specialize in this field since 2011. Our main business is 3D printing service, vacuum casting,CNC machining, plastic injection molding,and sheet matal Fabrication.Own over 200 professional staff and 2300+sets printing devices ,CNC machining center,drilling and milling machine etc.With these machines and experienced employees, we are able to provide strong guarantee for precision and strength parts. we stive to exceed our customer's expectation in all aspects of product manufacturing process, and recognize our great responsiblities to our customers,employees, suppiers and society. we keep adopting advanced production facilities to improve efficiency and ensure high and stable qualtity, and further reduce the production cost. The objective is to create reliable,viable and affordable prototype,plastic and metal parts and fast sample service for every industry

Why Choose YYI Tech

Whether you need new product development verification or personalized customization, YYI Tech can meet your needs

-

Integrated solution

20years experience and 20+professional engineering team, developing the most suitable comprehensive solution, optimize cost-effectiveness and benefit customers based on customers requirement

Integrated solution

20years experience and 20+professional engineering team, developing the most suitable comprehensive solution, optimize cost-effectiveness and benefit customers based on customers requirement -

One-stop service

Provide various services such as creating 3D drawings, rapid prototyping, small batch production, post-processing, secondary processing, assembly, assembly standard parts procurement, etc.

One-stop service

Provide various services such as creating 3D drawings, rapid prototyping, small batch production, post-processing, secondary processing, assembly, assembly standard parts procurement, etc. -

Powerful service capability

12 years of manufacturing experience, 20+professional engineering team, 300+ production equipment, complete processes and materials, able to provide the best solutions in a short time to meet customers' customized needs and design freedom

Powerful service capability

12 years of manufacturing experience, 20+professional engineering team, 300+ production equipment, complete processes and materials, able to provide the best solutions in a short time to meet customers' customized needs and design freedom

-

Fast delivery time

300+ devices are running continuously and can be delivered in as fast as one day while ensuring quality

Fast delivery time

300+ devices are running continuously and can be delivered in as fast as one day while ensuring quality -

High quality & Excellent price

A professional engineering team provides the best price solution while ensuring quality, maximizing customer benefits

High quality & Excellent price

A professional engineering team provides the best price solution while ensuring quality, maximizing customer benefits -

Data confidentiality

We have a strict internal confidentiality system and can sign NDA according to customer needs

Data confidentiality

We have a strict internal confidentiality system and can sign NDA according to customer needs

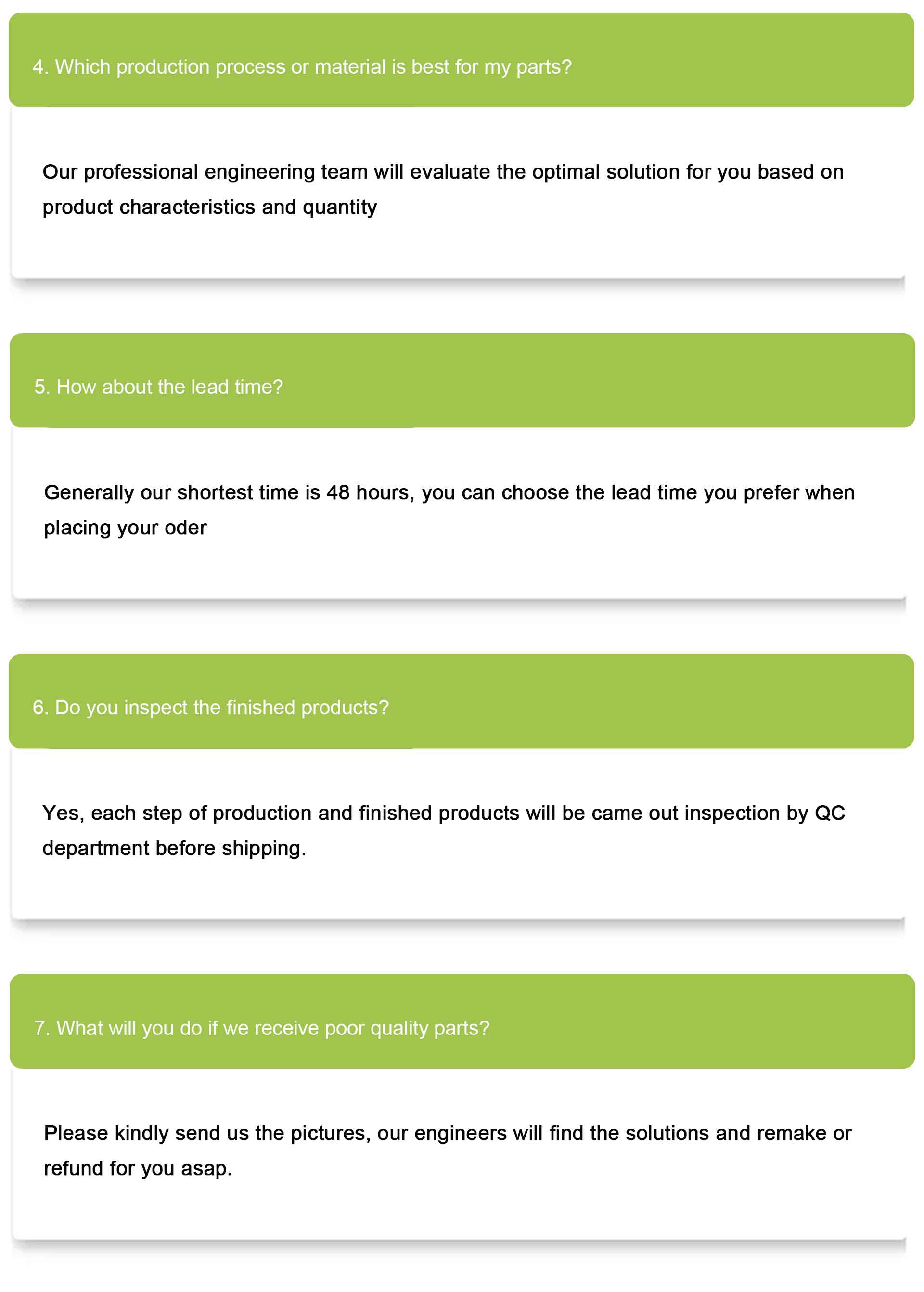

FAQ

prev Creating Perfect Moulds for Block Paving and Brick Making

next Bringing Nature and Durability Together Introducing Concrete Blocks with Grass