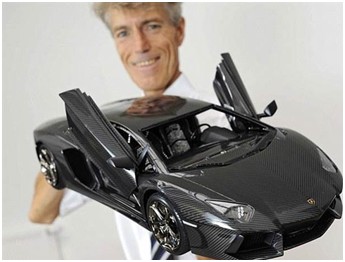

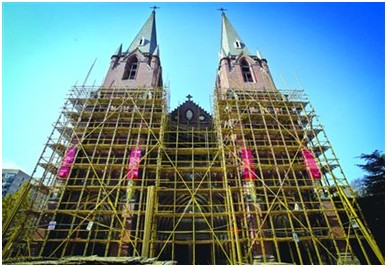

Completion of a building, from design concept to draw an image, and then finally begin to build is through many complicated steps. Before going into large-scale construction, we usually choose to build general look at 3D building models in future appearance.

People talk most about tech in this fast paced world must be 3D rendering, which is extremely beneficial for the architecture industry. 3D scale model making refers to a process of generating images based on three dimensional graphics using computers. The technology is used to successfully and clearly depict landscapes, buildings, roads as well as characters. With the benefits obvious with the technology, it has become extremely popular in the world of architects. Observing this trend, many building model makers have come forward to offer these services.

If you start analyzing its contribution in the field of architect, you would realize why these services have gained popularity. For builders or those dealing in real estate, it's always easier for them to win a client or investor when they have real like images to convince them. 3D models of any apartment or residential and commercial building like residential mansion scale models in full real-like colors and interactive features are easier to understand and visualize how they would appear when actually constructed. This is an element that is missing from the manual paper drawings, which are also hard to understand to those outside the industry like buyers or investors. Also, 3D plans allow making changes to the layout without significant investment or hassles.

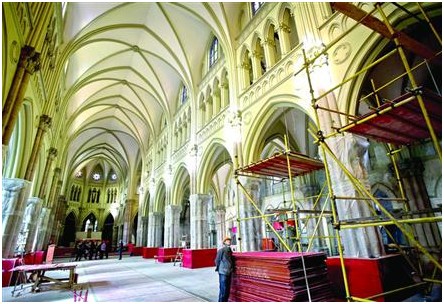

With the technology evolving significantly, rapid advances have been made in this regard. CAD and other technologies have evolved tremendously. Owing to this change, both residential and small scale commercial projects can benefit from the 3D technology. Buyers can now make an informed decision when it comes to purchasing their dream home. They can get the floor plan in real-like colors with all the elements placed accurately in the 3D images. This feature also allows them to make personalized changes to their home without increasing the cost.

3D architectural rendering services are referred to as photoreal for their lively nature. There are different types of renderings offered by service providers to their clients. If you want to have 3d model making for you house or buildings, you can visit http://www.bettymodels.com/ to get more information.

Related Reading: architectural model builders,3d landscape models,commercial house scale models

...